-

Mail

info@lehmann.com.tr

Cataphoresis painting is a process to increase corrosion resistance of exterior surface of the goods. It’s a electro coating process based on electrochemistry. The advantages of Cataphoresis painting system on others are;

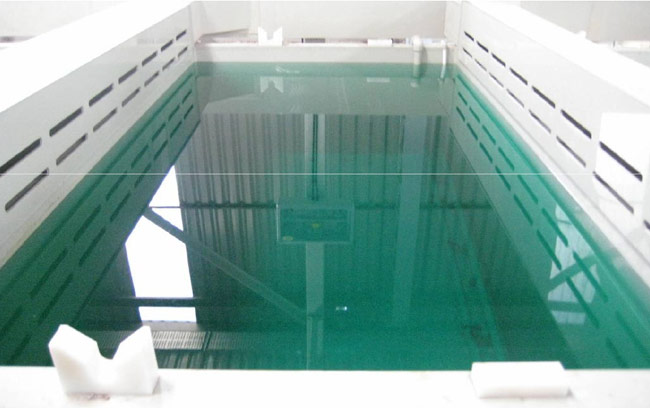

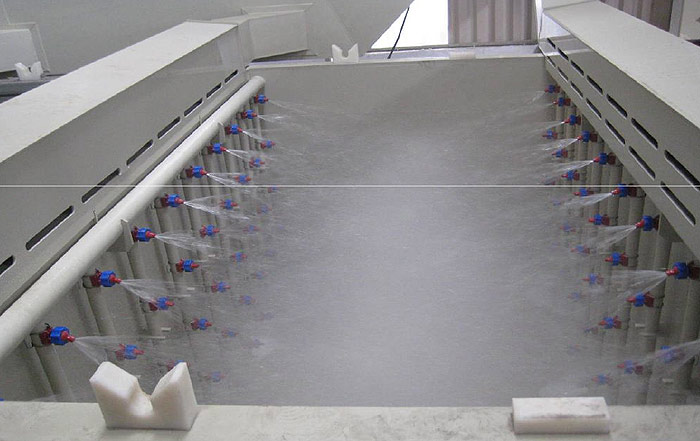

Full automatic cataphoresis line consists of 14 tanks with 3.000*1.500*1.800 mm dimensions. Cataphoresis line is controlled by 3 robots which work with laser control system. Robots have positioning ability on the tanks with 0.1 mm sensibility and 1.2 tons lifting capacity.

Cycle time is 80 minutes, conveyor route 78 meters and length of the burner is 32 meters. For every product a product prescription is prepared. The production process is fully automatic and operator only press start&stop button.

Our company which carries out its services in 3.000 m2 capacity and 1.000 m2 open area has ISO 9001; 2008 Quality Management System certificate, ISO 14001: 2015 Environmental Management System certificate, OHSAS 18001:2007 Occupational Health and Safety System certificate